Work kept me away from the T , and temps are slowly going down,

overhere.

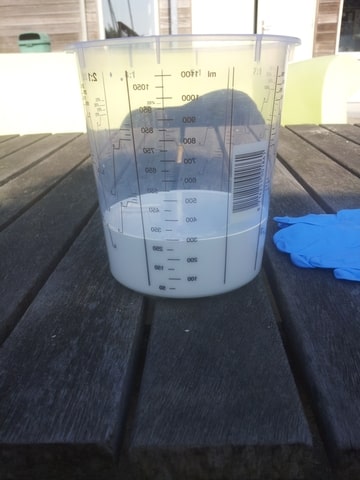

So, we sharpened our weapons (a 3Kw heater) and started on the primer.

We rolled the primer and let it cure in the garage at 20 degr C.

The result was a relief, finally no blisters or chemical reactions !!

But the hull is still not good enough for paint, to many little cracks

and dents.

So we had another round of putty and sanding.

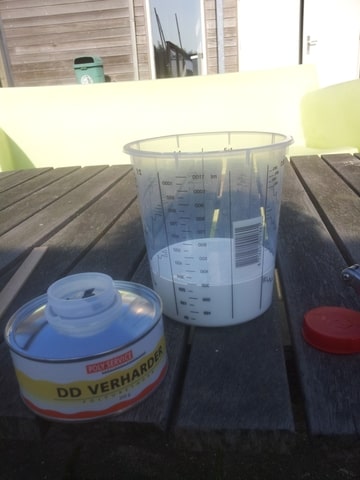

Had a good word with the paint/glass/epoxy-suplier , since the primer

finally "separated " the hull from the upcoming layers, he suggested

to finish the hull in polyurethane products and recommended 2

layers of topcoat, which is, in fact, a thick polyurethane coat to

smoothen the hull. And get rid of the last small ripples and bulbs.

And yes, Damon, we rolled and cured it inside !

Left the T with a smile today, tomorrow is sanding at 400 grain,

and next is hi-gloss paint.

Our club lets me use their garage for this project, but I am not

allowed to sand in the garage and in the weekends I have to take

out the hulls.

Takes a lot of planning this way, but I'm so happy with this club !!!

Keep You posted.

André

--

Tornado (80's Reg White)

Prindle 18-2 (sold)

Dart 16 (hired and hooked)

13 mtr steel cutter (sold)

Etap 22, unsinkable sailing pocket cruiser.

Amsterdam, the Netherlands

--