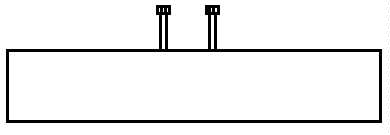

Making Your Own "Tramp Tightener"By Gary WillcoxI made my own "tramp tightener" for a couple of bucks. I took a 2x4 and cut it to about 18" length. Then got some honkin' lag bolts about 6-8" long. Then drilled two pilot holes in the center of the 2" side of the 2x4. Then cranked the lag bolts into the holes. Space the holes about 2" or so apart. Also purchase lag bolts that have threads on the lower 2/3rds or so - that way the exposed part of the bolts are smooth. The heads of the bolts help make the tramp rope not slip off.  Then you need some wedges. I bought the biggest honkin' dowel I could find. Then cut two pieces about 8" long. Then wip out your pocket knife and make a gradual taper like a carrot on the bottom half of the dowel. The tip should be a little smaller than the grommet plus rope you are using. Tie a bowline at one grommet up by the mast step. Lace just the center portion and tail off using the traveller cam. Then just place the two lag bolts of your new tool in each web of the tramp lacing and twist like spaghetti on a fork. Use the wedges to hold the line in the grommets as you "step" down each web portion of the tramp. Take up the slack as necessary at the traveller cam cleat. It's OK that you kneel on the tramp as you do this - the tool will make the tramp tight enough. Finish the rear of the tramp the same way. I like to have two pieces of rope for each side of the rear so I can use the traveller cam cleat in the same way as a third hand. Finish each segment with a couple of billion half hitches. This should get the tramp tight enough that the side rails bow in slightly. You may also need to buy a part from your Hobie dealer (Tramp Clamp by Tren Tec) to wedge in the side rails close to the tramp slot opening. This will eliminate the tramp from pulling out of the side rails at these spots. I'm not sure how long the rope should be total to cover all of the lacing. Note that some older tramps have "double grommets" and will require much more rope. I would use a rope that does not absorb water. Avoid the cotton shell stuff for this reason. You will have about 50' of rope that will add unwanted pounds when wet. Also get a prestretch or no stretch line or you will be re-tightening the tramp many times a season. Most people use a 6mm or 1/4" line (larger diameter will add more friction which will make tightening that much harder.) Of course you are doing this to avoid "independent suspension" of the hulls. To really reduce this "inherent feature" of the H16, you should drill out all the frame rivets, take the whole frame apart, clean, and epoxy the frame to corner castings and corner castings to pylons. The trick is to put the boat back together before the epoxy hardens. You also have to make sure that the boat is well aligned as you do this. I have yet to do this and hope to this Spring when it gets warm enough for the epoxy to set. I will report on how it goes. Back to Tech Tips |