Now, I do a lot of thinking and planning regarding some stuff I do, sometimes too much...simple is usually best in the beginning and almost always later.

I noticed end caps for NACRA boats and some others are quite spendy, if you can find them. I was looking and gave it up...

Then I found a piece of card board tube someone used to send something to me and wondered if the following to make a mold.

If it is the same OD as the beam? Yes...if so exactly and that includes the wall thickness, then

Why not carefully cut an inch or half-inch off the tube, the original end should be perfect...you can also remove inch to half inch of same dia and wall metal beam.

Seal one end with foil and decent glue so the closed end is flat and sealed...

Wrap masking or duct tape completely around the opposite end, say .25 to .5 inch above end, which creates a lip between the ID and OD of the tube...

Brush on a lot of Johnson's wax (happen to have old tin) as a releaser (you can heat to liquid)...

Maybe drop a circular piece of scrap fiberglass in, so it rests flat on the closed end...

Mix a batch of old epoxy and pour into the thing to the height over the tube edge for the desired lip...

Cure and voila! An end-cap that will fit...

And you can make as many as you want.

A bungee will hold them in, if need be...and the fit can be hand-filed to accommodate a given extrusion...

I have not tried it, too cold here, but soon...

A plan?

Edited by BobBill on Jan 20, 2015 - 03:40 PM.

--

Leave places better for having been there; respect others,

"The one thing that doesn't abide by majority rule is a person's conscience." Harper Lee - Scout, To Kill a Mockingbird.

Congress needs fixing, fix it!

--

End Caps for Cross Beams or Akas

- Rank: Lubber

- Registered: Jul 03, 2009

- Last visit: Feb 03, 2021

- Posts: 90

- Rank: Mate

- Registered: Jan 25, 2004

- Last visit: Apr 06, 2021

- Posts: 267

There've been a lot of ideas put forth before but I really think 3D printing is the way to go in making new endcaps. We just need someone to scan/plot/create their caps in a computer format and churn them out as needed. Just imagine, any color you want.

J

--

Aquacat 12 (sold)...'87 Nacra 5.8 (sold)...'03 Nacra Inter18 (sold)

Venture 15 (sold)....'89 Nacra 5.8 (sold)...'91 Nacra 5.8NA (sold)

'99 Nacra Inter20 (sold)

--

J

--

Aquacat 12 (sold)...'87 Nacra 5.8 (sold)...'03 Nacra Inter18 (sold)

Venture 15 (sold)....'89 Nacra 5.8 (sold)...'91 Nacra 5.8NA (sold)

'99 Nacra Inter20 (sold)

--

- Rank: Lubber

- Registered: Jul 14, 2004

- Last visit: Jan 21, 2015

- Posts: 84

- Rank: Lubber

- Registered: Apr 24, 2010

- Last visit: May 04, 2018

- Posts: 94

- Rank: Mate

- Registered: Feb 05, 2011

- Last visit: Jun 15, 2021

- Posts: 575

That looks great. Exactly what am I seeing here? Is that a PVC pipe cap that's been machined down, or is it two pieces?

Edited by gahamby on Jan 21, 2015 - 09:23 AM.

--

'82 Super Cat 15

Hull #315

Virginia

Previously owned: '70 H14, '79 H16, '68 Sailmaster 26, '85 H14T

--

Edited by gahamby on Jan 21, 2015 - 09:23 AM.

--

'82 Super Cat 15

Hull #315

Virginia

Previously owned: '70 H14, '79 H16, '68 Sailmaster 26, '85 H14T

--

- Rank: Lubber

- Registered: Apr 24, 2010

- Last visit: May 04, 2018

- Posts: 94

It is a schedule 40.....3" pvc pipe cap with a 3/4" piece of schedule 40 pvc glued and screwed to it. I had a post several years ago detailing the construction. Used a lot of epoxy butter and thin screws....kind of touchy...you don't want to drill through the cap. Most caps have a line to follow for cutting as a result of the moulding process. After 5yrs of use they were still good when I sold it. Check out my personal photos album also.

- Rank: Mate

- Registered: May 07, 2004

- Last visit: Nov 14, 2019

- Posts: 141

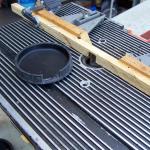

I took nacraman57 idea and changed it up a bit, I started with a 3" pvc pipe end cap, cut it down to 1" or so, ran it through a router table and made a 1 piece cap similar to the caps nacraman57 made.

there are more photos in the tech tips photos albums under N5.2 CAPS

http://www.thebeachcats.com/pictures?g2_itemId=108920

They fit very well bit I still put a few 1/2" #6 ss screws in so they don't come out.

--

Jeff O

N5.0

solcat 18(sold),

N5.2,

H16

Camarillo CA

--

there are more photos in the tech tips photos albums under N5.2 CAPS

http://www.thebeachcats.com/pictures?g2_itemId=108920

They fit very well bit I still put a few 1/2" #6 ss screws in so they don't come out.

--

Jeff O

N5.0

solcat 18(sold),

N5.2,

H16

Camarillo CA

--

- Rank: Lubber

- Registered: Jul 03, 2009

- Last visit: Feb 03, 2021

- Posts: 90

Much thanks. Weather here is in single digits but about to break...will be experimenting to find simplest. I have to order a piece of T6 tube and likely will add one 1" to 2" piece to use with epoxy just to see how the orig idea works. I live in small town and our two outlets which carry PVC seem not to have the sizes I would need...ID is 3.75"...my routing skill is wanting, but will see.

Edited by BobBill on Feb 25, 2015 - 02:25 AM.

--

Leave places better for having been there; respect others,

"The one thing that doesn't abide by majority rule is a person's conscience." Harper Lee - Scout, To Kill a Mockingbird.

Congress needs fixing, fix it!

--

Edited by BobBill on Feb 25, 2015 - 02:25 AM.

--

Leave places better for having been there; respect others,

"The one thing that doesn't abide by majority rule is a person's conscience." Harper Lee - Scout, To Kill a Mockingbird.

Congress needs fixing, fix it!

--

- Rank: Mate

- Registered: May 07, 2004

- Last visit: Nov 14, 2019

- Posts: 141

- Rank: Lubber

- Registered: Jul 03, 2009

- Last visit: Feb 03, 2021

- Posts: 90

Jeff, Thanks. It is still too cold here to epoxy...have had a piece of tube sitting by couch reminding me to have a half-inch or so cut off to do the job...soon though. For me, it should be a no-brainer to seal one end and tape the other, and pour in left-over mix until it gets about 1/8-inch over tape edge. Not as quick, but very doable. Thanks.

--

Leave places better for having been there; respect others,

"The one thing that doesn't abide by majority rule is a person's conscience." Harper Lee - Scout, To Kill a Mockingbird.

Congress needs fixing, fix it!

--

--

Leave places better for having been there; respect others,

"The one thing that doesn't abide by majority rule is a person's conscience." Harper Lee - Scout, To Kill a Mockingbird.

Congress needs fixing, fix it!

--