Just bought a 1983 Nacra 5.0. It's in great condition overall with one PITA problem:

https://drive.google.com/file/d/0B6l8KNLf9GRLSWtTdktpNXBqWW8/view?usp=sharing

This hole/tear is about 12" long and about 24" in front of the front crossbar. It didn't concern me too much when I bought the boat as I've sucessfully repaired a number of H16's and 18's with similar issues. My repair technique with the Hobies has been basically that suggested by Jamestown Distributors/West System:

https://www.youtube.com/watch?v=6N7YMr6E564

In planning my repair, I searched the forum for Nacra hull repair and found this photo:

https://drive.google.com/file/d/0B6l8KNLf9GRLaENRVEozbmIzLUk/view?usp=sharing

When I saw it, I thought HOLY CRAP!!!! If the damage is at arrow A, business as usual. If the damage is at arrow B, how in the world do you repair the stringers???

The easy way: A technique suggested by some is to not cut out the damage, but simply taper out from the crack an inch and a half or so all the way around, then lay the patch in.

The hard way: Cut out about an inch all the way around the crack, examine the hull interior with an inspection mirror for damage to the stringers then determine a final approach to the repair.

I have no idea how to repair the stringers. One poster discussing this type of repair suggested using a hammer and putty knife to "remove" the top of the hull non-skid area for access to make the repair. Removing that sounds like A LOT of work.

Opinions, suggestions, pictures and techniques from past repairs, tales from experience, magic fairy dust and prayers would be much appreciated.

Edited by leeboweffect on Apr 28, 2015 - 05:24 PM.

--

Hobie 16 (3 formerly)

MacGregor 25 (formerly)

Chrysler Dagger 14 (formerly)

NACRA 5.0 (currently)

High Point, NC

--

Nacra 5.0 Hull Repair - Opinions Please

- Rank: Mate

- Registered: Apr 22, 2015

- Last visit: May 21, 2023

- Posts: 484

- Rank: Chief

- Registered: Nov 26, 2009

- Last visit: Aug 10, 2024

- Posts: 2531

First off, make yourself an album, here...then upload hi res photos. That will help the next guy, & make it easier for members to see exactly what the damage is.

Probe with an automotive/dental pick, & determine if there is a stringer, & if the damage goes through it. It looks to be outer layer only, but hard to tell with the low quality photo.

You have choices for that tear, each with pros & cons.

I would remove the hull, so you can lay it flat on a couple saw horses, & use gravity to level the epoxy/filler.

The easy & fast way is to just use an angle grinder & carefully remove the damaged material, feathering outwards. You should be at an 8:1 ratio, a 1/8" gap needs to feather about 1".

The stringer is just a cardboard tube with fabric/epoxy. If torn it is easy (with hull on side) to push a bit of wetted cloth through the gap, onto the stringer & "paint" it into place. Depending on how wide the gap is, it might be easier to "paint" the inside of the stringer, then push dry fabric through & tap it into place with a paint mix stick. Work some thickened epoxy onto the fabric while the first layer is still green, & add another layer if needed.

The cons are cosmetic, you WILL have a 1", or bigger stripe down that nice shiny hull that WILL take some work & skill to hide. The glass repair is easy,(but the cured epoxy is ugly, (even when mixed with microfibres, it won't be nearly as white as the hull), finishing it a few mm below the existing hull, then gelcote, fairing & color match ...not so easy.

One other option is to grind/repair from the outside, then cover the patch with some sort of graphic. You will have to come up with something that doesn't look like a decal hiding a hole.

Or bite the bullet & remove the front deck. Easy access & lots of room to work. You should be able to use a small angle grinder, or a dremel with grinding ball to feather from the inside, away from the damage. If the stringer is broken, grind it off, fix the hull, then use an adequately sized piece of paper towel tube etc, or any bit of plastic tube as a form & lay up a new section of stringer, it is much easier than it sounds. Overlap the ends of the stringer patch 3-4 inches, so it acts as a continuous beam.

This way sounds harder, BUT;

The deck comes off & re-attaches pretty easy-use thickened epoxy(microfibres) so any gaps between hull & deck are fully bonded.

Grind very carefully, from the inside, so as not to open up a gap. You should be able to leave a thin layer, along with the gelcote. When covered with a new piece of red speedline tape afterwards, it will be almost invisible.

Once prepped, place a layer of packing tape along the tear, on the outside of the hull. This will prevent epoxy from seeping through, & nearly eliminate sanding.

Flip the hull on its side & lay up your repair, from the inside. It won't matter if your patch extends 3" each side of the tear, it's inside/invisible. If the tear is just above/below the stringer, just smooth the fabric over the stringer.

Replace deck,(tape around it so no epoxy drips/runs will adhere to hull).

Redo the damaged bit of speedline, the repair will now be almost unnoticeable.

Resist the urge to start mixing epoxy! Prep & planning are more difficult than mixing/glassing.

--

Hobie 18 Magnum

Dart 15

Mystere 6.0XL Sold Was a handful solo

Nacra 5.7

Nacra 5.0

Bombardier Invitation (Now officially DEAD)

Various other Dock cluttering WaterCrap

--

Probe with an automotive/dental pick, & determine if there is a stringer, & if the damage goes through it. It looks to be outer layer only, but hard to tell with the low quality photo.

You have choices for that tear, each with pros & cons.

I would remove the hull, so you can lay it flat on a couple saw horses, & use gravity to level the epoxy/filler.

The easy & fast way is to just use an angle grinder & carefully remove the damaged material, feathering outwards. You should be at an 8:1 ratio, a 1/8" gap needs to feather about 1".

The stringer is just a cardboard tube with fabric/epoxy. If torn it is easy (with hull on side) to push a bit of wetted cloth through the gap, onto the stringer & "paint" it into place. Depending on how wide the gap is, it might be easier to "paint" the inside of the stringer, then push dry fabric through & tap it into place with a paint mix stick. Work some thickened epoxy onto the fabric while the first layer is still green, & add another layer if needed.

The cons are cosmetic, you WILL have a 1", or bigger stripe down that nice shiny hull that WILL take some work & skill to hide. The glass repair is easy,(but the cured epoxy is ugly, (even when mixed with microfibres, it won't be nearly as white as the hull), finishing it a few mm below the existing hull, then gelcote, fairing & color match ...not so easy.

One other option is to grind/repair from the outside, then cover the patch with some sort of graphic. You will have to come up with something that doesn't look like a decal hiding a hole.

Or bite the bullet & remove the front deck. Easy access & lots of room to work. You should be able to use a small angle grinder, or a dremel with grinding ball to feather from the inside, away from the damage. If the stringer is broken, grind it off, fix the hull, then use an adequately sized piece of paper towel tube etc, or any bit of plastic tube as a form & lay up a new section of stringer, it is much easier than it sounds. Overlap the ends of the stringer patch 3-4 inches, so it acts as a continuous beam.

This way sounds harder, BUT;

The deck comes off & re-attaches pretty easy-use thickened epoxy(microfibres) so any gaps between hull & deck are fully bonded.

Grind very carefully, from the inside, so as not to open up a gap. You should be able to leave a thin layer, along with the gelcote. When covered with a new piece of red speedline tape afterwards, it will be almost invisible.

Once prepped, place a layer of packing tape along the tear, on the outside of the hull. This will prevent epoxy from seeping through, & nearly eliminate sanding.

Flip the hull on its side & lay up your repair, from the inside. It won't matter if your patch extends 3" each side of the tear, it's inside/invisible. If the tear is just above/below the stringer, just smooth the fabric over the stringer.

Replace deck,(tape around it so no epoxy drips/runs will adhere to hull).

Redo the damaged bit of speedline, the repair will now be almost unnoticeable.

Resist the urge to start mixing epoxy! Prep & planning are more difficult than mixing/glassing.

--

Hobie 18 Magnum

Dart 15

Mystere 6.0XL Sold Was a handful solo

Nacra 5.7

Nacra 5.0

Bombardier Invitation (Now officially DEAD)

Various other Dock cluttering WaterCrap

--

- Rank: Mate

- Registered: Apr 22, 2015

- Last visit: May 21, 2023

- Posts: 484

Thanks Ed and sorry about the photos looking so small they are almost all resized to 1400 pixels on the largest side, but don't show large and hi-res when opened in google drive's picture viewer. If you dl and open them, they're pretty crisp. I haven't figured out the album thing yet, but working on it.

Turns out that today I'm perhaps the luckiest cat sailor around. Very carefully Dremeled along the crack with the rotary file bit. When I got a slot tracing the crack to about 3/16" wide and flexed the upper or lower edge of the slot I could see inside the hull very clearly both up and down. I have the situation at arrow A in my second photo above. The crack is slightly closer to the upper stringer, but easily enough to position a backer, taper out etc. w/o any stringer repair.

BTW, the skin on my hulls at the area I'm repairing is no more than 0.090 if that. It seems super thin.

I'm going to save the text from your reply in my files for future reference.

Is there a video or step by step instructions w/ photos for the deck removal process??

--

Hobie 16 (3 formerly)

MacGregor 25 (formerly)

Chrysler Dagger 14 (formerly)

NACRA 5.0 (currently)

High Point, NC

--

Turns out that today I'm perhaps the luckiest cat sailor around. Very carefully Dremeled along the crack with the rotary file bit. When I got a slot tracing the crack to about 3/16" wide and flexed the upper or lower edge of the slot I could see inside the hull very clearly both up and down. I have the situation at arrow A in my second photo above. The crack is slightly closer to the upper stringer, but easily enough to position a backer, taper out etc. w/o any stringer repair.

BTW, the skin on my hulls at the area I'm repairing is no more than 0.090 if that. It seems super thin.

I'm going to save the text from your reply in my files for future reference.

Is there a video or step by step instructions w/ photos for the deck removal process??

--

Hobie 16 (3 formerly)

MacGregor 25 (formerly)

Chrysler Dagger 14 (formerly)

NACRA 5.0 (currently)

High Point, NC

--

- Rank: Administrator

- Registered: Jul 19, 2001

- Last visit: Feb 20, 2025

- Posts: 3455

leeboweffect,

Instructions for the photo albums and showing them here are lnked in my sig below.

--

Damon Linkous

1992 Hobie 18

Memphis, TN

How To Create Your Signature

How To Create Your Own Cool Avatar

How To Display Pictures In The Forums.

--

Instructions for the photo albums and showing them here are lnked in my sig below.

--

Damon Linkous

1992 Hobie 18

Memphis, TN

How To Create Your Signature

How To Create Your Own Cool Avatar

How To Display Pictures In The Forums.

--

- Rank: Chief

- Registered: Nov 26, 2009

- Last visit: Aug 10, 2024

- Posts: 2531

????

Your boat used solid glass, no cored hulls, they have to be reasonably thin or the weight goes way up.

Here is a link to a total 5.2 rebuild, contains some info re deck removal. What also works well is one of those little reciprocating gizmos for sanding tight spaces. They come with either a sanding, cutting or razor attachment. I don't have a photo of mine, & can't remember the proper name.

http://www.radesignz.com/nacra5.2redo.htm

Reading your last post, & with sailing season upon us, if it were my boat, & based on being able to flex the hull enough to see clearly inside, and with no stringer damage, I would fix it from the outside. It will look almost as good, & be an easy project. When finished either paint/speedtape the repair, try your hand at gelcote, or bug Damon for a BeachCats sticker & plaster it on.

Of course you could also use any other graphic you desire.

Feather out from the tear 1/8" either side of center. The strength of this repair will be on the inside. The less you grind outside, the less visible will be the repair.

Use whatever you have to pry the edges apart. Bend a strip of sheet metal into an "L", & wrap some cloth around the short end. Wet with acetone, then flex the hull so you can insert it & wipe down the inside. You just want to clean any crap off the fibreglass so new material will adhere. Before cleaning I used course sandpaper on one repair, but that might be overkill.

Tape the outside of the hull so no epoxy gets outside the perimeter of the patch, this will greatly speed the final steps of the repair.

Lay hull on sawhorses, damaged side down,(you are going to work underneath at first).

Next make a patch using say 4 layers of cloth, & a strip of plastic juice jug, or similar stiff yet flexible material the same size as the patch.

Make the patch a couple inches longer than the tear, & say 2" wide.

Punch a line of small holes in the plastic strip every few inches, & lay the cloth layers on top. Using a needle, thread something like parachute cord, through the fabric & plastic strip, leaving it hang down 12" or so,(only on the cloth side) at each loop.

You now have 4 layers of cloth, backed with a flexible plastic strip, all held together with strong thread.

Fully wet, (using slow hardener, you will need some working time), for this small of job just pour it on & tap into the fabric with a finger. I would add some micro fibres to stiffen the mixture somewhat. Let the patch slightly cure, but have everything ready so you can accomplish the next step while it is still quite flexible.

Now comes the tricky part,

Generously smear epoxy onto the inside of the hull & onto the green patch, pry apart the edges, & insert the patch, edgewise through the slit, plastic strip up, & manouvre into position, strings hanging out. With the patch "slightly green", you will have some stiffness, & so be able to maneuver it inside the hull, yet it will be quite flexible & adhere to the inside contour of the hull when pulled into place & held with the strings. Hang weights from the strings, using enough to make the patch contour.

With the hull positioned damage side down, gravity will keep the epoxy where you want it.

Some epoxy will dribble out, wipe it off, right down to the original fibreglass,(you did tape the perimeter, right?) Once cured, cut the strings, the repair will be slightly below the gelcote level.

Depending on how you want to do the final finish determines your final action. If painting or just doing the speedline, you can now add a layer or two of fabric to the outside, & sand smooth.

I would STRONGLY advise you make a first patch,(only need a couple layers of fabric) & use that for a dry run. That will teach you exactly how you are going to insert & secure the patch & how long it will remain flexible. You can work out any snags, with no clock running. Once you have it figured, make the real patch & do the job.

I have used SS lockwire a couple of times, but I think something like parachute cord, or masons string is better.

You are going to mix quite small batches of resin, have a way to accurately measure the quantities required.

If you are going to document the project, have a helper take photos. From experience I know you are too busy, or don't want to touch your camera with messy hands.

Edited by Edchris177 on Apr 28, 2015 - 09:10 PM.

--

Hobie 18 Magnum

Dart 15

Mystere 6.0XL Sold Was a handful solo

Nacra 5.7

Nacra 5.0

Bombardier Invitation (Now officially DEAD)

Various other Dock cluttering WaterCrap

--

Your boat used solid glass, no cored hulls, they have to be reasonably thin or the weight goes way up.

Here is a link to a total 5.2 rebuild, contains some info re deck removal. What also works well is one of those little reciprocating gizmos for sanding tight spaces. They come with either a sanding, cutting or razor attachment. I don't have a photo of mine, & can't remember the proper name.

http://www.radesignz.com/nacra5.2redo.htm

Reading your last post, & with sailing season upon us, if it were my boat, & based on being able to flex the hull enough to see clearly inside, and with no stringer damage, I would fix it from the outside. It will look almost as good, & be an easy project. When finished either paint/speedtape the repair, try your hand at gelcote, or bug Damon for a BeachCats sticker & plaster it on.

Of course you could also use any other graphic you desire.

Feather out from the tear 1/8" either side of center. The strength of this repair will be on the inside. The less you grind outside, the less visible will be the repair.

Use whatever you have to pry the edges apart. Bend a strip of sheet metal into an "L", & wrap some cloth around the short end. Wet with acetone, then flex the hull so you can insert it & wipe down the inside. You just want to clean any crap off the fibreglass so new material will adhere. Before cleaning I used course sandpaper on one repair, but that might be overkill.

Tape the outside of the hull so no epoxy gets outside the perimeter of the patch, this will greatly speed the final steps of the repair.

Lay hull on sawhorses, damaged side down,(you are going to work underneath at first).

Next make a patch using say 4 layers of cloth, & a strip of plastic juice jug, or similar stiff yet flexible material the same size as the patch.

Make the patch a couple inches longer than the tear, & say 2" wide.

Punch a line of small holes in the plastic strip every few inches, & lay the cloth layers on top. Using a needle, thread something like parachute cord, through the fabric & plastic strip, leaving it hang down 12" or so,(only on the cloth side) at each loop.

You now have 4 layers of cloth, backed with a flexible plastic strip, all held together with strong thread.

Fully wet, (using slow hardener, you will need some working time), for this small of job just pour it on & tap into the fabric with a finger. I would add some micro fibres to stiffen the mixture somewhat. Let the patch slightly cure, but have everything ready so you can accomplish the next step while it is still quite flexible.

Now comes the tricky part,

Generously smear epoxy onto the inside of the hull & onto the green patch, pry apart the edges, & insert the patch, edgewise through the slit, plastic strip up, & manouvre into position, strings hanging out. With the patch "slightly green", you will have some stiffness, & so be able to maneuver it inside the hull, yet it will be quite flexible & adhere to the inside contour of the hull when pulled into place & held with the strings. Hang weights from the strings, using enough to make the patch contour.

With the hull positioned damage side down, gravity will keep the epoxy where you want it.

Some epoxy will dribble out, wipe it off, right down to the original fibreglass,(you did tape the perimeter, right?) Once cured, cut the strings, the repair will be slightly below the gelcote level.

Depending on how you want to do the final finish determines your final action. If painting or just doing the speedline, you can now add a layer or two of fabric to the outside, & sand smooth.

I would STRONGLY advise you make a first patch,(only need a couple layers of fabric) & use that for a dry run. That will teach you exactly how you are going to insert & secure the patch & how long it will remain flexible. You can work out any snags, with no clock running. Once you have it figured, make the real patch & do the job.

I have used SS lockwire a couple of times, but I think something like parachute cord, or masons string is better.

You are going to mix quite small batches of resin, have a way to accurately measure the quantities required.

If you are going to document the project, have a helper take photos. From experience I know you are too busy, or don't want to touch your camera with messy hands.

Edited by Edchris177 on Apr 28, 2015 - 09:10 PM.

--

Hobie 18 Magnum

Dart 15

Mystere 6.0XL Sold Was a handful solo

Nacra 5.7

Nacra 5.0

Bombardier Invitation (Now officially DEAD)

Various other Dock cluttering WaterCrap

--

- Rank: Chief

- Registered: Nov 26, 2009

- Last visit: Aug 10, 2024

- Posts: 2531

I should have added, make sure the repair area is dry. I don't now how much water got in, open any hatches & drains. You can use a heat lamp on the outside to dry the inside.

You can do this repair with hull on boat, but thicken the epoxy to ketchup consistency when inserting the patch, & make sure you figure out a means to tension the strings so they contour the patch properly.

--

Hobie 18 Magnum

Dart 15

Mystere 6.0XL Sold Was a handful solo

Nacra 5.7

Nacra 5.0

Bombardier Invitation (Now officially DEAD)

Various other Dock cluttering WaterCrap

--

You can do this repair with hull on boat, but thicken the epoxy to ketchup consistency when inserting the patch, & make sure you figure out a means to tension the strings so they contour the patch properly.

--

Hobie 18 Magnum

Dart 15

Mystere 6.0XL Sold Was a handful solo

Nacra 5.7

Nacra 5.0

Bombardier Invitation (Now officially DEAD)

Various other Dock cluttering WaterCrap

--

- Rank: Mate

- Registered: Apr 22, 2015

- Last visit: May 21, 2023

- Posts: 484

Ed, thanks again for all the great advise.

dl = down load

Google drives's picture viewer doesn't open photos full size, however if you click one of my links to bring up the photo, then click on the download arrow at the top to download it to your hard drive when you open it with your computer's picture viewer it will be full size. Clunky I know, but it's the only way I could throw up a few photos fast. I'm working on the photo album thing via the link DamonLinkous posted above.

--

Hobie 16 (3 formerly)

MacGregor 25 (formerly)

Chrysler Dagger 14 (formerly)

NACRA 5.0 (currently)

High Point, NC

--

dl = down load

Google drives's picture viewer doesn't open photos full size, however if you click one of my links to bring up the photo, then click on the download arrow at the top to download it to your hard drive when you open it with your computer's picture viewer it will be full size. Clunky I know, but it's the only way I could throw up a few photos fast. I'm working on the photo album thing via the link DamonLinkous posted above.

--

Hobie 16 (3 formerly)

MacGregor 25 (formerly)

Chrysler Dagger 14 (formerly)

NACRA 5.0 (currently)

High Point, NC

--

- Rank: Chief

- Registered: Nov 26, 2009

- Last visit: Aug 10, 2024

- Posts: 2531

I guess that should have been obvious...I got it to work.

Using the method I outlined, that will be the strongest part of the hull,you are very lucky, don't grind outside the red stripe, then you can just paint over, or find some matching tape & your fix will be invisible. Do it wothout removing the hull.

You can fill those long score marks using a $15 gelcote repair kit if desired.

--

Hobie 18 Magnum

Dart 15

Mystere 6.0XL Sold Was a handful solo

Nacra 5.7

Nacra 5.0

Bombardier Invitation (Now officially DEAD)

Various other Dock cluttering WaterCrap

--

- Rank: Mate

- Registered: Apr 22, 2015

- Last visit: May 21, 2023

- Posts: 484

A few progress photos of the repair to date:

See full album 3 photos:

http://www.thebeachcats.com/pictures?g2_itemId=113616

All cancer removal was done with a Dremel tool using a rotary file bit.

Working outside here. Waiting for the rain and cloudy skies to end before continuing.

--

Hobie 16 (3 formerly)

MacGregor 25 (formerly)

Chrysler Dagger 14 (formerly)

NACRA 5.0 (currently)

High Point, NC

--

See full album 3 photos:

http://www.thebeachcats.com/pictures?g2_itemId=113616

All cancer removal was done with a Dremel tool using a rotary file bit.

Working outside here. Waiting for the rain and cloudy skies to end before continuing.

--

Hobie 16 (3 formerly)

MacGregor 25 (formerly)

Chrysler Dagger 14 (formerly)

NACRA 5.0 (currently)

High Point, NC

--

- Rank: Mate

- Registered: Apr 22, 2015

- Last visit: May 21, 2023

- Posts: 484

Another thing I have encountered is that as I cut out the damage, the bottom edge moved outward from the top edge.

The offset of the bottom edge to the top edge is about 1/16". This must be from residual stress being relieved as material is removed. Obviously, these edges will have to be aligned and held in place while the repair is being made.

--

Hobie 16 (3 formerly)

MacGregor 25 (formerly)

Chrysler Dagger 14 (formerly)

NACRA 5.0 (currently)

High Point, NC

--

The offset of the bottom edge to the top edge is about 1/16". This must be from residual stress being relieved as material is removed. Obviously, these edges will have to be aligned and held in place while the repair is being made.

--

Hobie 16 (3 formerly)

MacGregor 25 (formerly)

Chrysler Dagger 14 (formerly)

NACRA 5.0 (currently)

High Point, NC

--

- Rank: Chief

- Registered: Nov 26, 2009

- Last visit: Aug 10, 2024

- Posts: 2531

1/16" isn't much. When you do your dry fit, you may find that pulling the patch so it contours is enough to realign the two edges.

If not, try removing tension from the tramp, and/or judiciously placing a weight on the high side, though the hull will have to be on its side.

Is the hull masked, or did you remove all 3 stripes? Hopefully the former, it is easier to hide 12" of a single stripe than all three.

--

Hobie 18 Magnum

Dart 15

Mystere 6.0XL Sold Was a handful solo

Nacra 5.7

Nacra 5.0

Bombardier Invitation (Now officially DEAD)

Various other Dock cluttering WaterCrap

--

If not, try removing tension from the tramp, and/or judiciously placing a weight on the high side, though the hull will have to be on its side.

Is the hull masked, or did you remove all 3 stripes? Hopefully the former, it is easier to hide 12" of a single stripe than all three.

--

Hobie 18 Magnum

Dart 15

Mystere 6.0XL Sold Was a handful solo

Nacra 5.7

Nacra 5.0

Bombardier Invitation (Now officially DEAD)

Various other Dock cluttering WaterCrap

--

- Rank: Mate

- Registered: Apr 22, 2015

- Last visit: May 21, 2023

- Posts: 484

Ed, after noodling it a bit, here is what I've come up with to get the alignment dead on:

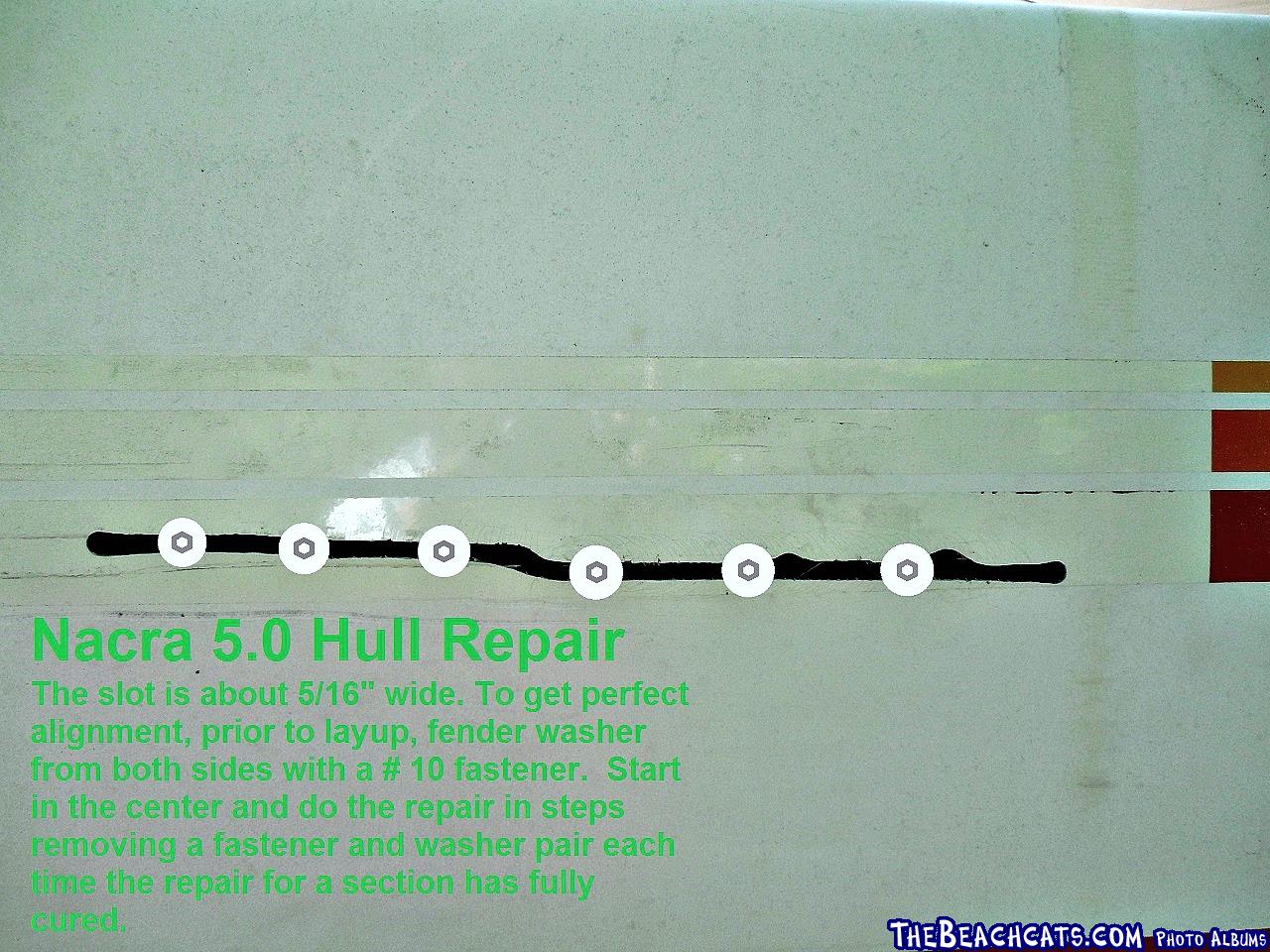

Sorry that the annotation in the photo is fuzzy. It was crystal clear on my screen opening it from my HDD. Some how when I uploaded it to the album???? It's legible, but you may have to squint.

Basically a # 10 fender washer on both sides of the hull being pulled together with a # 10 fastener (just nice and snug not gorilla tight). Space the washers about every 2" along the slot and do the repair about 2" at a time starting in the center and removing a washer set after each section is complete and cured. Time consuming I know, but what I've come up with so far.

I stole this technique from experience in metal fab. We used to hold steel plates together in this fashion prior to welding when alignment was critical.

Yes, I did remove the stripes.

TGIF

--

Hobie 16 (3 formerly)

MacGregor 25 (formerly)

Chrysler Dagger 14 (formerly)

NACRA 5.0 (currently)

High Point, NC

--

Sorry that the annotation in the photo is fuzzy. It was crystal clear on my screen opening it from my HDD. Some how when I uploaded it to the album???? It's legible, but you may have to squint.

Basically a # 10 fender washer on both sides of the hull being pulled together with a # 10 fastener (just nice and snug not gorilla tight). Space the washers about every 2" along the slot and do the repair about 2" at a time starting in the center and removing a washer set after each section is complete and cured. Time consuming I know, but what I've come up with so far.

I stole this technique from experience in metal fab. We used to hold steel plates together in this fashion prior to welding when alignment was critical.

Yes, I did remove the stripes.

TGIF

--

Hobie 16 (3 formerly)

MacGregor 25 (formerly)

Chrysler Dagger 14 (formerly)

NACRA 5.0 (currently)

High Point, NC

--

- Rank: Administrator

- Registered: Jul 19, 2001

- Last visit: Feb 20, 2025

- Posts: 3455

Probably just the color of the letters against that background and maybe the editor made the letters slightly transparant?

To make it easier to add descriptions to your photos you can use the "Edit Captions" link in your album and edit all the titles, and descriptions at once. That way the text will be searchable by the site search and by Google in case someone is looking for this type of repair in the future.

--

Damon Linkous

1992 Hobie 18

Memphis, TN

How To Create Your Signature

How To Create Your Own Cool Avatar

How To Display Pictures In The Forums.

--

- Rank: Mate

- Registered: Apr 22, 2015

- Last visit: May 21, 2023

- Posts: 484

- Rank: Chief

- Registered: Nov 26, 2009

- Last visit: Aug 10, 2024

- Posts: 2531

You're over thinking it.

Decades ago, I did a semester of welding, I understand the idea of tacking things together, & not overheating & distorting metal. I have an AC/DC arc welder in the garage at my lake house, great for building/fixing dock frames & other stuff, but we are not dealing with metal here.

In this case nothing will distort, BUT, you will end up with a weaker fix. Unlike welding, If you go at it a few inches at a time it will be very difficult to bond each 2" section to those adjoining it, the smaller the hole gets the harder to overlap each section of patch.

Use one piece, & you will have a continuous "stringer" bonded to the hull.

Try a dry fit, using any thin material, I think you will find that the low side will easily pull out to match the other.

Just figure out how to McGyver something to tie the strings off to. IF you do it with the hull on the boat, it could be as simple as a 2x4 nailed across 2 saw horses. Weight the horses so they can't move, then drive nails into the 2x4 every few inches, so you can wrap & tension each string individually.

I used this method to fix a 2 foot tear in the bottom of an old Invitation dinghy,(very similar to a Laser) I set the boat on two saw horses so the strings were vertical, & used 5 or 6 pieces of broken brick as weights. The entire job only took a few hours, I used cheap 3M Bondo expoxy that kicked in 20 minutes, & we sailed a few hours later.

--

Hobie 18 Magnum

Dart 15

Mystere 6.0XL Sold Was a handful solo

Nacra 5.7

Nacra 5.0

Bombardier Invitation (Now officially DEAD)

Various other Dock cluttering WaterCrap

--

- Rank: Mate

- Registered: Feb 18, 2013

- Last visit: Jul 19, 2015

- Posts: 396

IF you can compress the halfs together with straps simply epoxy both sides of crack and then squeeze together fill and sand. Otherwise you'll need to place backing to hold filler material in the channel you've created. I might try cutting up bleach bottle strips, using thin welding rod as pull handles to fashion backing structure then fill channel with wetted 4oz fb cloth, sand, fill, sand etc... until smooth. Same as drywall hole repair between joyces yet using epoxy not spackling.

Edited by goodsailing on May 03, 2015 - 10:59 PM.

--

Goodsailing

Laser-Standard Rig (Sold 6/15)

H18 (Sold 7/15)

Building 19' Tacking Outrigger

Balt-Wash Area

--

Edited by goodsailing on May 03, 2015 - 10:59 PM.

--

Goodsailing

Laser-Standard Rig (Sold 6/15)

H18 (Sold 7/15)

Building 19' Tacking Outrigger

Balt-Wash Area

--

- Rank: Mate

- Registered: Apr 22, 2015

- Last visit: May 21, 2023

- Posts: 484

Ed and goodsailing thanks for your input. I'm still formulating a final approach to the repair. Won't start laying glass for another week or so. Currently waiting on ordered materials. Please keep noodling, all input is welcome.

--

Hobie 16 (3 formerly)

MacGregor 25 (formerly)

Chrysler Dagger 14 (formerly)

NACRA 5.0 (currently)

High Point, NC

--

--

Hobie 16 (3 formerly)

MacGregor 25 (formerly)

Chrysler Dagger 14 (formerly)

NACRA 5.0 (currently)

High Point, NC

--

- Rank: Mate

- Registered: Feb 18, 2013

- Last visit: Jul 19, 2015

- Posts: 396

Us composites 1:4 quick epoxy... great stuff and cheaper and easier to use than west etc

Try strip of fb wetted cloth on top of bleach bottle plastic, slit through opening, pull close with thin metal welding rod secure with applied pressure to hold structure, cure, sand, fill etc. Once backing is cured you can fill pretty easy.. U may be able to tape the rods to the hull to create the pressure needed. ..you'll figure it out... its not that hard to do..

Edited by goodsailing on May 03, 2015 - 11:04 PM.

--

Goodsailing

Laser-Standard Rig (Sold 6/15)

H18 (Sold 7/15)

Building 19' Tacking Outrigger

Balt-Wash Area

--

Try strip of fb wetted cloth on top of bleach bottle plastic, slit through opening, pull close with thin metal welding rod secure with applied pressure to hold structure, cure, sand, fill etc. Once backing is cured you can fill pretty easy.. U may be able to tape the rods to the hull to create the pressure needed. ..you'll figure it out... its not that hard to do..

Edited by goodsailing on May 03, 2015 - 11:04 PM.

--

Goodsailing

Laser-Standard Rig (Sold 6/15)

H18 (Sold 7/15)

Building 19' Tacking Outrigger

Balt-Wash Area

--

- Rank: Mate

- Registered: Feb 18, 2013

- Last visit: Jul 19, 2015

- Posts: 396

He used string... you'll get the idea

Get some micro balloons to add to epoxy for gap filling. The brown stuff. Use this after getting the backing done and don't use this to wet the cloth, won't saturate.

https://www.youtube.com/watch?v=V6EnxtqwBsQ

Edited by goodsailing on May 03, 2015 - 11:14 PM.

--

Goodsailing

Laser-Standard Rig (Sold 6/15)

H18 (Sold 7/15)

Building 19' Tacking Outrigger

Balt-Wash Area

--

Get some micro balloons to add to epoxy for gap filling. The brown stuff. Use this after getting the backing done and don't use this to wet the cloth, won't saturate.

https://www.youtube.com/watch?v=V6EnxtqwBsQ

Edited by goodsailing on May 03, 2015 - 11:14 PM.

--

Goodsailing

Laser-Standard Rig (Sold 6/15)

H18 (Sold 7/15)

Building 19' Tacking Outrigger

Balt-Wash Area

--

- Rank: Mate

- Registered: Apr 22, 2015

- Last visit: May 21, 2023

- Posts: 484

goodsailing, thanks for the advice/tips and video. I have seen that video previously. He's quite good with glass, how quickly and confidently he lays it, particularly working outdoors, which is my current situation. There's nothing quite like planning a layup, cutting out the pieces and then having a nice big puff of wind blow them off your workbench (a sheet of plywood over two sawhorses). Have you noticed, the wind always blows when you don't want it to and when you're sailing to a destination, it's always on your nose?!??!?!?

--

Hobie 16 (3 formerly)

MacGregor 25 (formerly)

Chrysler Dagger 14 (formerly)

NACRA 5.0 (currently)

High Point, NC

--

--

Hobie 16 (3 formerly)

MacGregor 25 (formerly)

Chrysler Dagger 14 (formerly)

NACRA 5.0 (currently)

High Point, NC

--

- Rank: Master Chief

- Registered: Jun 20, 2006

- Last visit: Dec 04, 2024

- Posts: 7090

no offense but i disagree on materials suggested - I would spend the money and use proven products

use west system - proven and takes gel-coat after (good to have around for future needs)

I would use mill fiber (has other names) - it will give strength to your epoxy, micro balloons only add air/body (texture for thickening).

use west system - proven and takes gel-coat after (good to have around for future needs)

I would use mill fiber (has other names) - it will give strength to your epoxy, micro balloons only add air/body (texture for thickening).

- Rank: Mate

- Registered: Apr 22, 2015

- Last visit: May 21, 2023

- Posts: 484

No worry MN3, I'm a huge West System 105/205 fan(206 slow hardener for summer time 80 deg. plus) and would not use anything else.

I buy all my cloth here:

http://www.fibreglast.com/

Edited by leeboweffect on May 05, 2015 - 11:29 PM.

--

Hobie 16 (3 formerly)

MacGregor 25 (formerly)

Chrysler Dagger 14 (formerly)

NACRA 5.0 (currently)

High Point, NC

--

I buy all my cloth here:

http://www.fibreglast.com/

Edited by leeboweffect on May 05, 2015 - 11:29 PM.

--

Hobie 16 (3 formerly)

MacGregor 25 (formerly)

Chrysler Dagger 14 (formerly)

NACRA 5.0 (currently)

High Point, NC

--

- Rank: Mate

- Registered: Feb 18, 2013

- Last visit: Jul 19, 2015

- Posts: 396

True, balloons have no structural aspects so it depends upon how much of a crack you're trying to fill etc. I've put fb tape over fillet of balloon thickened epoxy and then wetted cloth to form acceptable seems on stitch and glue. I've used both West and US Composites. I used west fast in 70 degrees and it still took 1 hour to set...it also blushed. I would never use slow for small job like being talked about. You do realize there's only several manufactures of resin components in the country. West, US Composites and others get their epoxy from these sources and private label with their own branding. Insuring there are no voids or air underneath resin is more important than the brand of epoxy most used, West, MAS US composites,Raka, system 3 etc. IMO. I have 2 part Perfection over Us Composites on a roof of utility trailer and it looks as good now as when I painted it.. years ago. Roof, sun, rain snow etc...

But, after you experiment with materials yourself you'll come to your own conclusions.. The 1:5 mix for oz quantities of west was PITA plus too thick for me.

Edited by goodsailing on May 05, 2015 - 02:35 PM.

--

Goodsailing

Laser-Standard Rig (Sold 6/15)

H18 (Sold 7/15)

Building 19' Tacking Outrigger

Balt-Wash Area

--

- Rank: Master Chief

- Registered: Jun 20, 2006

- Last visit: Dec 04, 2024

- Posts: 7090

- Rank: Chief

- Registered: Nov 26, 2009

- Last visit: Aug 10, 2024

- Posts: 2531

It will all "blush", unless you use the "clear" hardener, made for applications like cedar strip canoes etc. I used it to apply a wear strip down the bottoms of the 6M Mystere. It cured absolutely clear, invisible from 10'.

Here is a filler guide, I have mostly used microfibres, strong, cures to an off white,(depending on how much you used) yet sands OK. Collodial silica is the strongest, but a b*tch to sand, & shows through .

http://www.westsystem.com/ss/fillers

Setting time is temperature dependent, but not wholly outside air temp. If you mix a full cup, it will get hot, & kick much quicker. If you pour it out into a shallow pan, you will triple the pot life.

For hardener choice;

http://www.westsystem.com…ardener-selection-guide/

I bought a gallon of epoxy, it drops the coat in half...& I know I'm going to break something else down th e road.

--

Hobie 18 Magnum

Dart 15

Mystere 6.0XL Sold Was a handful solo

Nacra 5.7

Nacra 5.0

Bombardier Invitation (Now officially DEAD)

Various other Dock cluttering WaterCrap

--

- Rank: Mate

- Registered: Apr 22, 2015

- Last visit: May 21, 2023

- Posts: 484

Ed, another trick I read somewhere to increase pot life and open time is to refrigerate both components prior to mixing. Never tried it, but it makes sense.

--

Hobie 16 (3 formerly)

MacGregor 25 (formerly)

Chrysler Dagger 14 (formerly)

NACRA 5.0 (currently)

High Point, NC

--

--

Hobie 16 (3 formerly)

MacGregor 25 (formerly)

Chrysler Dagger 14 (formerly)

NACRA 5.0 (currently)

High Point, NC

--

- Rank: Mate

- Registered: Feb 18, 2013

- Last visit: Jul 19, 2015

- Posts: 396

I don't worry about pot life as after 1 min mix it's poured out. What are you guys doing with the pot that you worry about it setting up in the pot? You may be mixing too much. Try mixing only what you need as all you mix should be put down after a minute or so mixing. Unless doing patch work, then use small quantities. balloon mix will set faster the thicker you make it.

Blush is no problem, simple wash with clean water.. don't even need soap.

--

Goodsailing

Laser-Standard Rig (Sold 6/15)

H18 (Sold 7/15)

Building 19' Tacking Outrigger

Balt-Wash Area

--

Blush is no problem, simple wash with clean water.. don't even need soap.

--

Goodsailing

Laser-Standard Rig (Sold 6/15)

H18 (Sold 7/15)

Building 19' Tacking Outrigger

Balt-Wash Area

--

- Rank: Chief

- Registered: Nov 26, 2009

- Last visit: Aug 10, 2024

- Posts: 2531

I have never tried it on boat repairs, we generally do not get the heat that the Southern States experience. I did try it once with a product called Git Rot.

I was fixing a soft end of a leg on a 200 year old dining table, & wanted the max time for the product to soak into the existing wood.

When I did the wear strips on the Mystere, temps were around 30C, (86F) & there was lots of time to "paint" the entire length, lay on cloth, & paint again, using West/clear hardener. You will have ample time to manouvre the strip inside the hull while it is still pliable. Even if organized, it can easily take more than 10 minutes to get it placed & secured, as often you overlook some detail & have to improvise, with the clock running.

I used the 3M Bondo stuff on the SS Minnow & it would kick in minutes, was only good for simple jobs, & it cures to a brownish color..

--

Hobie 18 Magnum

Dart 15

Mystere 6.0XL Sold Was a handful solo

Nacra 5.7

Nacra 5.0

Bombardier Invitation (Now officially DEAD)

Various other Dock cluttering WaterCrap

--

- Rank: Mate

- Registered: Apr 22, 2015

- Last visit: May 21, 2023

- Posts: 484

Here are a few repair update photos:

Backer stock preparation:

The perfect backer:

First backer in:

Seventh backer in:

Now bevel around the perimeter, install the outside finish patch and paint. Not sure how fast progress will be as we're in a blazing he!! right now in NC with 95 +- highs everyday.

--

Hobie 16 (3 formerly)

MacGregor 25 (formerly)

Chrysler Dagger 14 (formerly)

NACRA 5.0 (currently)

High Point, NC

--

Backer stock preparation:

The perfect backer:

First backer in:

Seventh backer in:

Now bevel around the perimeter, install the outside finish patch and paint. Not sure how fast progress will be as we're in a blazing he!! right now in NC with 95 +- highs everyday.

--

Hobie 16 (3 formerly)

MacGregor 25 (formerly)

Chrysler Dagger 14 (formerly)

NACRA 5.0 (currently)

High Point, NC

--

- Rank: Lubber

- Registered: Apr 24, 2014

- Last visit: Apr 09, 2017

- Posts: 98

- Rank: Chief

- Registered: Nov 26, 2009

- Last visit: Aug 10, 2024

- Posts: 2531

That spring is a real good idea, greatly simplifies tying off the tension lines.

Your backers are thicker than the original hull, that will be the stiffest part of the boat.

Just curious, did you cut the top photo into 2" squares?

Why not slip the entire backer in end first, then pull into place with 4-5 strings, leaving it as a continuous patch?

Grind very little on the outside, keep the width to what will be covered by the speedline, the fix will then be invisible. You don't need a ton of strength on the outside, what you placed on the inside is stronger than th e original hull.

Now get that baby back in the water, those boats are a ton of fun, both solo or two up.

--

Hobie 18 Magnum

Dart 15

Mystere 6.0XL Sold Was a handful solo

Nacra 5.7

Nacra 5.0

Bombardier Invitation (Now officially DEAD)

Various other Dock cluttering WaterCrap

--

Your backers are thicker than the original hull, that will be the stiffest part of the boat.

Just curious, did you cut the top photo into 2" squares?

Why not slip the entire backer in end first, then pull into place with 4-5 strings, leaving it as a continuous patch?

Grind very little on the outside, keep the width to what will be covered by the speedline, the fix will then be invisible. You don't need a ton of strength on the outside, what you placed on the inside is stronger than th e original hull.

Now get that baby back in the water, those boats are a ton of fun, both solo or two up.

--

Hobie 18 Magnum

Dart 15

Mystere 6.0XL Sold Was a handful solo

Nacra 5.7

Nacra 5.0

Bombardier Invitation (Now officially DEAD)

Various other Dock cluttering WaterCrap

--

- Rank: Mate

- Registered: Apr 22, 2015

- Last visit: May 21, 2023

- Posts: 484

- Rank: Mate

- Registered: Apr 22, 2015

- Last visit: May 21, 2023

- Posts: 484

Ed, the top photo shows the backers in the raw, as cast. They are made from 4" wide 9 oz. tape, 2 plys. Each ply is about 0.010" thick. Total thickness after curing is about 0.024".

Yes, they were cut in to 2" X 2" squares after curing. A single strip would have been wonderful, stronger and much faster, but the fender washer technique I used to keep the top and bottom edges aligned forced the one 2 X 2 at a time approach.

Note, I measured the hull (skin) thickness including gel coat = 0.045" by my vernier.

--

Hobie 16 (3 formerly)

MacGregor 25 (formerly)

Chrysler Dagger 14 (formerly)

NACRA 5.0 (currently)

High Point, NC

--

Yes, they were cut in to 2" X 2" squares after curing. A single strip would have been wonderful, stronger and much faster, but the fender washer technique I used to keep the top and bottom edges aligned forced the one 2 X 2 at a time approach.

Note, I measured the hull (skin) thickness including gel coat = 0.045" by my vernier.

--

Hobie 16 (3 formerly)

MacGregor 25 (formerly)

Chrysler Dagger 14 (formerly)

NACRA 5.0 (currently)

High Point, NC

--