I have a 2000 Nacra 450 with about an inch wide strip of exposed glass on the keels so figure it's time for a bottom job. Leakage is fairly minimal right now - maybe a cup or two of water in each hull after a few hours on the water - and I'd like to keep it that way. This will be the first time I've done this so I'm hoping some of the old salts here can let me know if I'm about to go far wrong.

I'm planning to use the large Bondo fiberglass repair kit as it's cheap, seems to have the right amount of material and polyester resin shouldn't have any bonding issues with gelcoat. I plan to lay down a layer of the woven mat in the areas with the most wear to fill and level them, a layer of 2 inch wide cloth (purchased separately) over this extending the full length of the keel where I want to add material, then follow up with another later of mat in the areas where I want to add more material for shaping/fairing. The wear strip seems to be flat while the rest of the keels are a rounded V, so I'd like to get close to the original shape.

Once all that is sanded I plan to brush on a single coat of gelcoat over the entire length of the keel.

Just to note, where I'll be doing the work is outdoors and I have no power available, so a cordless drill is the extent of the power tools I'll have available.

Am I missing anything?

Bottom Job Plan

- Rank: Lubber

- Registered: Jan 22, 2020

- Last visit: Nov 15, 2022

- Posts: 8

- Rank: Mate

- Registered: Jun 15, 2016

- Last visit: Apr 14, 2022

- Posts: 181

My advice would be to use epoxy rather than resin. Epoxy bonds well to cured resin. Resin does not bond well to cured resin. Once the resin is cured, you can only get a physical bond. Epoxy makes great physical bonds to resin. Resin does not. Resin makes great chemical bonds when the bonding surface is not yet fully cured, such as when taping bulkheads to tacky (recently laid) hulls. I've seen similar advice on this forum. I once attached polyester to cured polyester, and it was easy to peel off. West System epoxy is expensive, but is utterly reliable. There may be less expensive epoxy options, but I have no experience with them. Cloth applied to hulls laid up-side-down may be the easiest route. One layer may suffice and require less fairing. You may want to consider something like peel ply to reduce sanding effort. I've used electrical tape over curing epoxy as well. I am unsure if gelcoat will work over West System epoxy. If you go the WS epoxy route, G-Flex is easy to work with and wets out glass OK. Mix small amounts as larger amounts will flash over before your are ready to apply.

Edited by traphappy on Jan 22, 2020 - 04:51 PM.

Edited by traphappy on Jan 22, 2020 - 04:51 PM.

- Rank: Lubber

- Registered: Jan 22, 2020

- Last visit: Nov 15, 2022

- Posts: 8

- Rank: Mate

- Registered: Apr 15, 2004

- Last visit: Jan 13, 2023

- Posts: 358

I have done this on a 4.5. At the time Perf Cats told me the boat was built with polyester. I used polyester with no problem. But I would still use epoxy. If you use polyester make sure to really sand the old surface thoroughly. And there’s two kinds of resin. There’s laminating resin which is used for all layers except the last where you use the finishing resin. I think the finishing resin contains some kind of wax that helps it cure. But if used in the laminating layers will cause them to not stick. My info my be out of date or just plain wrong.

--

Tim

Collierville (Memphis), TN

Supercat 15--sold :(

Hobie monocat--given

Vanguard 15--traded for...

Nacra 4.5--sold

Nacra 5.7

Hobie 14–sold to make room for...

Supercat 17–sold

--

--

Tim

Collierville (Memphis), TN

Supercat 15--sold :(

Hobie monocat--given

Vanguard 15--traded for...

Nacra 4.5--sold

Nacra 5.7

Hobie 14–sold to make room for...

Supercat 17–sold

--

- Rank: Mate

- Registered: Jun 15, 2016

- Last visit: Apr 14, 2022

- Posts: 181

- Rank: Mate

- Registered: Jun 30, 2018

- Last visit: Feb 12, 2025

- Posts: 601

If you go epoxy, i found the Total Epoxy, by Jamestown to be identical in performance, tensile strength, etc. to West and be a little cheaper. Ive been using the slow catalyst. Epoxy is also way more predictable for me. Properly prepared surfaces and epoxy have been 100% reliable for me whether polyester, vinylester, aluminum or wood. Wash and degrease thoroughly BEFORE you start sanding otherwise you just drive it into the fiberglass and you can end up getting fish eyes in the top of the resin. Ive read on Fibreglasts website, I think that polyester gelcoat can be made to work with epoxy, but there's some trick to it that I forget. Ive never had the opportunity to try it.

good luck!

--

Chuck C

NACRA 500 Mk2

Hobie 21se (sold)

--

good luck!

--

Chuck C

NACRA 500 Mk2

Hobie 21se (sold)

--

- Rank: Mate

- Registered: Mar 19, 2004

- Last visit: Apr 08, 2025

- Posts: 965

The most important factors for getting a good bond are surface prep and cleanliness. You can use epoxy, but personally, for this application, I would use polyester resin. My general rule of thumb is that for internal structural repairs (where you need a really good bond and the strongest resin and where gelcoating is not needed) use epoxy. For external non-structural repairs where you intend to gelcoat, use polyester. Again, if you prep the surface well and keep it clean, getting a good bond should not be a problem. That means cleaning the repair area well to remove dirt. Then sanding thoroughly with 80-150 grit paper. And finally wiping everything clean with acetone.

Personally, I would not use Bondo brand materials. The stuff you get at Home Depot is low quality. Go to a fiberglass supplier and get some decent materials - they will be easier to work with and give you better results in the long run. Otherwise, your approach sounds about right.

sm

Personally, I would not use Bondo brand materials. The stuff you get at Home Depot is low quality. Go to a fiberglass supplier and get some decent materials - they will be easier to work with and give you better results in the long run. Otherwise, your approach sounds about right.

sm

- Rank: Mate

- Registered: Jun 30, 2018

- Last visit: Feb 12, 2025

- Posts: 601

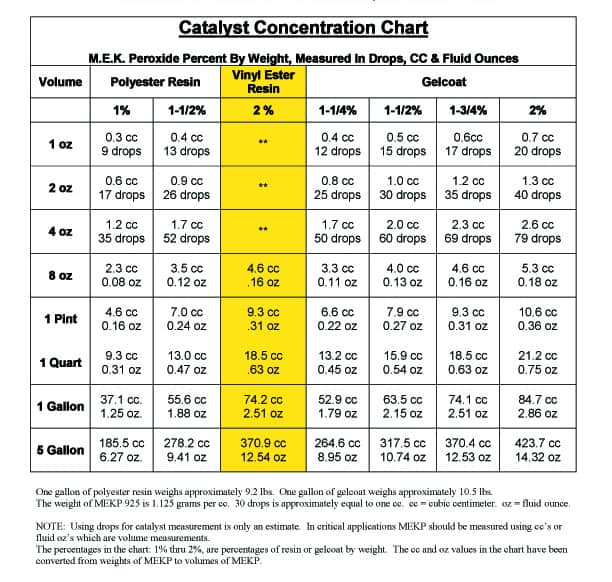

Standard polyester laminating resin is much cheaper and reliably compatible with gel coat as well..there are advantages... Make sure you play with it first, attempting to catalyze it at a given temperature so you can figure out how long you have to work with it...try laminating glass to a piece of wood and see how smooth you can get it, noting when the resin turns to the "green" state (stop before it gets to this gel state), otherwise, messy bad things happen...

I'd personally love to have the option to fix hull with gelcoat, but my hull is already painted. If you do use some type of filler, make sure it's "waterproof" as standard Bondo filler is not; it'll allow water absorption if you have any kind of leak, like a scratch. Dynatron is one that is waterproof and polyester; there are others.

--

Chuck C

NACRA 500 Mk2

Hobie 21se (sold)

--

I'd personally love to have the option to fix hull with gelcoat, but my hull is already painted. If you do use some type of filler, make sure it's "waterproof" as standard Bondo filler is not; it'll allow water absorption if you have any kind of leak, like a scratch. Dynatron is one that is waterproof and polyester; there are others.

--

Chuck C

NACRA 500 Mk2

Hobie 21se (sold)

--

- Rank: Master Chief

- Registered: Jun 20, 2006

- Last visit: Dec 04, 2024

- Posts: 7090

if you don't have a lot of experience i would look at youtube for a while for tips and techniques

The west system videos with the english guy are fantastic

(there are 3 in this series) - https://www.youtube.com/watch?v=_5uqyfiaufU

i would definitely turn the boat upside down and let it dry out 100% if there is any chance of moisture

I would paper/mask off all areas that are close to your repair area

if you think you may wear down this area again in the future you may consider using west system 422 Barrier Coat Additive or similar

"Barrier Coat Additive is a proprietary blend designed to further improve cured epoxy’s moisture exclusion effectiveness. 422 is used as a barrier coating additive to help prevent gelcoat blistering in polyester fiberglass boats. 422 also increases the epoxy’s abrasion resistance. Cures to a light gray color." -https://www.westsystem.co…2-barrier-coat-additive/

fairing the skegs should be pretty easy but when you move forward and the skegs blend into the bow area it may be a little trickier . be sure to mask off the area you are going to work in.

it gets tricky when you are fairing off the new gelcoat - it can be hard to see where it ends and the old gelcoat starts (you don't want to take off any extra)

I did a bottom job recently and found "brushing" on gelcoat to be futile.

the tip and roll method is probably much better but requires 2 people and still is not a perfect system

Edited by MN3 on Jan 23, 2020 - 02:12 PM.

The west system videos with the english guy are fantastic

(there are 3 in this series) - https://www.youtube.com/watch?v=_5uqyfiaufU

i would definitely turn the boat upside down and let it dry out 100% if there is any chance of moisture

I would paper/mask off all areas that are close to your repair area

if you think you may wear down this area again in the future you may consider using west system 422 Barrier Coat Additive or similar

"Barrier Coat Additive is a proprietary blend designed to further improve cured epoxy’s moisture exclusion effectiveness. 422 is used as a barrier coating additive to help prevent gelcoat blistering in polyester fiberglass boats. 422 also increases the epoxy’s abrasion resistance. Cures to a light gray color." -https://www.westsystem.co…2-barrier-coat-additive/

fairing the skegs should be pretty easy but when you move forward and the skegs blend into the bow area it may be a little trickier . be sure to mask off the area you are going to work in.

it gets tricky when you are fairing off the new gelcoat - it can be hard to see where it ends and the old gelcoat starts (you don't want to take off any extra)

I did a bottom job recently and found "brushing" on gelcoat to be futile.

the tip and roll method is probably much better but requires 2 people and still is not a perfect system

Edited by MN3 on Jan 23, 2020 - 02:12 PM.

- Rank: Mate

- Registered: Oct 26, 2017

- Last visit: Sep 06, 2024

- Posts: 133

This past summer I did a small fiberglass repair and gelcoat under significant adult supervision. I repaired a hole on the very bottom of the hull. While I could have rolled this, since the area I was applying gelcoat was only about half an inch wide, I used a foam brush. The biggest challenge I saw was mixing the right amount of gelcoat and reaction agent when using less than the full can. For one coat, I didn’t add enough agent and it was still tacky the following day.

--

Dana, Holly, Emma & Hannah

LJ/Stu's Dart 18 (Sold! :( )

--

--

Dana, Holly, Emma & Hannah

LJ/Stu's Dart 18 (Sold! :( )

--

- Rank: Master Chief

- Registered: Jun 20, 2006

- Last visit: Dec 04, 2024

- Posts: 7090

- Rank: Mate

- Registered: Oct 26, 2017

- Last visit: Sep 06, 2024

- Posts: 133

- Rank: Mate

- Registered: Mar 19, 2004

- Last visit: Apr 08, 2025

- Posts: 965

Temperature definitely also affects cure time. Hotter ambient temp will result in a shorter cure time. Also the vessel that the resin is mixed in. Essentially, the chemical reaction that causes the resin to change from liquid to solid both generates heat while it occurs and requires heat to occur. If you mix up a bunch of resin in a pot it will build up heat and cure faster, generating more heat, curing even faster (a chain reaction called “exotherm”).

Once the resin is out of the pot and spread onto a large surface (like the hull), the cure speed will slow significantly.

Definitely worth messing around with the resin on some scrap parts (pieces of wood or something) to familiarize yourself with how it works before diving into a full on hull repair.

sm

Once the resin is out of the pot and spread onto a large surface (like the hull), the cure speed will slow significantly.

Definitely worth messing around with the resin on some scrap parts (pieces of wood or something) to familiarize yourself with how it works before diving into a full on hull repair.

sm