Lets start a thread about Soft Shackles.

Where to use

How to make

where to buy

where NOT to use em, etc

Soft Shackles - where, how, why, why not

- Rank: Master Chief

- Registered: Jun 20, 2006

- Last visit: Dec 04, 2024

- Posts: 7090

- Rank: Master Chief

- Registered: Jun 20, 2006

- Last visit: Dec 04, 2024

- Posts: 7090

I started with a 3mm and 4mm selma fid

they make it pretty easy

I used 3 or 4 mm 8 strand or 12 strand single braind (no jacket) and learned eye splicing and lock stitches

pretty easy stuff

then i learned a few other splices: like a brummel locking splice and Mobius Brummel Eye Splice

I now use a brion toss splicing wand

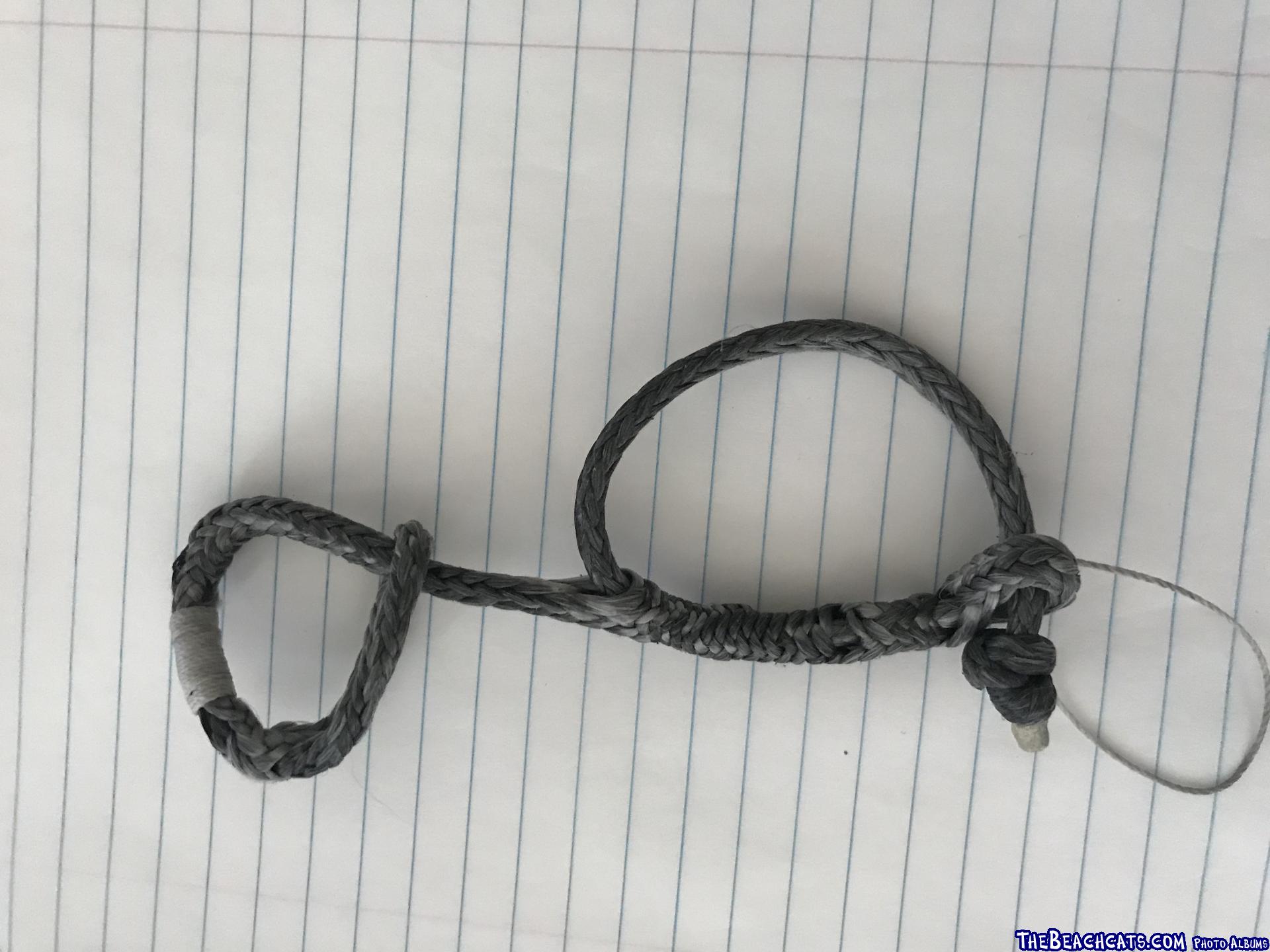

and this is my most recent splice

for my buddies downhaul -

luggage tag for the downhaul blocks, soft shackle for the tack of the sail

Edited by MN3 on Jul 09, 2020 - 11:20 AM.

they make it pretty easy

I used 3 or 4 mm 8 strand or 12 strand single braind (no jacket) and learned eye splicing and lock stitches

pretty easy stuff

then i learned a few other splices: like a brummel locking splice and Mobius Brummel Eye Splice

I now use a brion toss splicing wand

and this is my most recent splice

for my buddies downhaul -

luggage tag for the downhaul blocks, soft shackle for the tack of the sail

Edited by MN3 on Jul 09, 2020 - 11:20 AM.

- Rank: Mate

- Registered: Oct 26, 2016

- Last visit: Feb 14, 2025

- Posts: 235

Where: everywhere

When - when you are bored - you need a small number of tools, and lengths of rope. Once you get the hang of it, the number of tools and time needed go down severely.

Why/where not:

- serious chafe

- need a hard ring (ie: mainsail halyard)

- needs to be released under load

When - when you are bored - you need a small number of tools, and lengths of rope. Once you get the hang of it, the number of tools and time needed go down severely.

Why/where not:

- serious chafe

- need a hard ring (ie: mainsail halyard)

- needs to be released under load

- Rank: Lubber

- Registered: Aug 04, 2013

- Last visit: Aug 09, 2021

- Posts: 48

Are they a good choice for jib sheet? I am thinking being lightweight would help to not collapse the jib in very light air, but is there a risk of the lazy sheet coming off as not under load the pull the soft shackle taught? Any particular considerations when looking at making them for this purpose?

- Rank: Master Chief

- Registered: Jun 20, 2006

- Last visit: Dec 04, 2024

- Posts: 7090

- Rank: Chief

- Registered: Nov 26, 2009

- Last visit: Aug 10, 2024

- Posts: 2531

I use them on any jibs that do not stay rigged all season. This one was from my 6.0XL Mystere, (20’ x 10’).

I have used it on the Hobie 18, & even on my 15’ Dart. The Dart has a pretty small jib, I would make one out of smaller line.

It takes no skill at making splices or loops, merely a few knots. You can see the jib blocks are secured by a knot. After hoisting the jib, simply slide the loop through the clew, then put the monkey fist into the loop. At the end of the day, it is taken off without untying anything, or requiring a shackle dog.

I’ve used it for years, & it has never come undone.

https://www.thebeachcats.com/pictures?g2_itemId=133337

Sorry,mthesendamned ipads don’t give me a valid link to post the photo direct.

Got a real computer...

Edited by Edchris177 on Jul 20, 2020 - 08:18 PM.

--

Hobie 18 Magnum

Dart 15

Mystere 6.0XL Sold Was a handful solo

Nacra 5.7

Nacra 5.0

Bombardier Invitation (Now officially DEAD)

Various other Dock cluttering WaterCrap

--

- Rank: Mate

- Registered: Oct 26, 2016

- Last visit: Feb 14, 2025

- Posts: 235

My jib uses soft shackles on head, tack and crew.

For the main, the boom "strap" at the clew and the cunningham attachment are soft shackles. All the blocks attached to the boom are on soft shackles.

My boat is stored mast up. When I come to rig it to sail, it's all soft shackles or stuff in cleats, with the main halyard being the only exception. Takes longer to get the sailors dressed than to get the boat dressed.

For the main, the boom "strap" at the clew and the cunningham attachment are soft shackles. All the blocks attached to the boom are on soft shackles.

My boat is stored mast up. When I come to rig it to sail, it's all soft shackles or stuff in cleats, with the main halyard being the only exception. Takes longer to get the sailors dressed than to get the boat dressed.

- Rank: Master Chief

- Registered: Jun 20, 2006

- Last visit: Dec 04, 2024

- Posts: 7090

I hope you don't shackle your crew

:)

http://sail-delmarva.blog…-stropes-and-square.html

Soft Shackles, Stropes, and Square Riggers

Amsteel and other high-tech lines have made crazy things practical...

All-fiber standing rigging

Fiber lifelines

Safer jacklines

Fiber shackles

... except now that I think about it, none of this is completely new. It's where we started, when the first sailor decided to raise a few sticks and a woven mat above his raft to save paddling home. Clearly, we've improved on those early efforts. First, we used tarred steel, and then stainless steel. Heavier and more expensive, but durable and non-stretch with great abrasion resistance. But we couldn't leave it alone. I'm glad.

Traditional spliced strope with wall knot stopper

One of the biggest trends we've seen in the past 50 years is away from things that can be made to things that must be purchased. Given the steady decline in the basic shop skills of the average sailor and the increase in the complexity of our world, this trend is unstopable. But I try. Many of us try, and that is one of the great attractions of Amsteel; that a DIY sailor can replace purchased rigging services and create something better. I like that too.

Soft Shackles. A cool little invention: the only thing is the idea is about 200 years old on boats, and as old as ropes in general. Every pre-teen girl learned to tie these when braiding friendship bracelets. Every old salt learned to tie a strop with a splice and a turkshead; They are strong, cheap, and won't jam if loaded sharply. I've seen them used to arrest cannon. Rather similar, I think.

Still a good idea today. When made from Amsteel...

As strong as steel

Won't scratch the gel coat

Light

Cheap

Quiet

No tools required to install of remove

Edited by MN3 on Jul 20, 2020 - 02:36 PM.