Cool trailer mods

-

- Rank: Chief

- Registered: Apr 19, 2011

- Last visit: Dec 10, 2024

- Posts: 1461

This is true, and on newer hulls especially. The key here is a custom fit- not just to the hulls, but to the place where boat and trailer meet. If the support fits the hull snugly and is lined up perfectly on the trailer crossbar wiithout any side-slip, you have a great situation. But if the form-fitted support can slide inches sideways in the wind while you are trailering, the hulls can twist in the snug cradle and be damaged. Every boat/trailer/owner is a little different in terms of where the crossbars contact the keels while trailering, so custom is a necessity in a lot of cases.

A local cat sailor just laid up his own fiberglass cradles by using his upside down hulls as the template, padded the surface with outdoor carpeting and did not go very high up the sides- maybe 5 or 6 vertical inches. Even if the strap loosens a little while trailering (like in the rain), his hulls will stay put.

So your point about making the "V" in the cradles wider as they move up is a smart thought. Give the hulls a little wiggle room, but not enough to allow them to shift sideways.

Accurate. Longer is better than higher. In my thought the best cradles would be an inverted T when you looked at them from the side. Visualize a long (say 16") bottom under the hulls with a tapering side support narrowing to a 3" wide tip.

--

Sheet In!

Bob

_/)_____/)_/)____/)____/)_____/)/)__________/)__

Prindle 18-2 #244 "Wakizashi"

Prindle 16 #3690 "Pegasus" Sold (sigh)

AZ Multihull Fleet 42 member

(Way) Past Commodore of Prindle Fleet 14

Arizona, USA

-- -

- Rank: Mate

- Registered: Jul 06, 2008

- Last visit: Jul 19, 2018

- Posts: 986

I'll probably end up with something like that for my H17 but it will just across the beams of me P18. An 8 ft sec of 2x6 pressure treated lumbar then I'm going to get some 2x4 pressure treated and rip an angle cut down one edge on 2 boards and screw the angled edge to the flat side of the 2x6 all along it creating a kind of bowl.

--

Dustin Finlinson • Magna, UT

Member: Utah Sailing Association

1982 Prindle 18

1986 Hobie 17

1982 Prindle 16

1980 Prindle 16(mostly)

1976 Prindle 16(mostly)

Check out "Prindle Sailors" on Facebook.

-- -

- Rank: Mate

- Registered: Apr 24, 2011

- Last visit: Mar 20, 2018

- Posts: 177

-

- Rank: Mate

- Registered: Aug 13, 2010

- Last visit: Mar 10, 2014

- Posts: 294

Zach. Your plan is based on attaching the cradles to the trailer frame.. I am working on a design that would allow mounting the cradles on the shaft that the rollers were on by using a small tube attached to the Cradles.. Gives movement in the aft mounting to pivit (spell??) and accept the hulls when loading. With a bit of clearance in the length, it lets the cradles slide a bit to accept the hulls and there is no re-drilling of the mounts, just pull the rollers and slip in the cradles.. . Will do a pix thing soon .. IM if you want some pix soon. What kind of covers ar you doing?? Cheers Hal

--

Hal Liske

Livermore CA

H 16 (6+ 1.. Friends) H 3.2 N 5.2 (2) H 17 (2) H-18

Nacra 5.8 (son's) H 20 (Friends)

It's a Sickness

I Need a A Cat Please

-- -

- Rank: Mate

- Registered: Apr 24, 2011

- Last visit: Mar 20, 2018

- Posts: 177

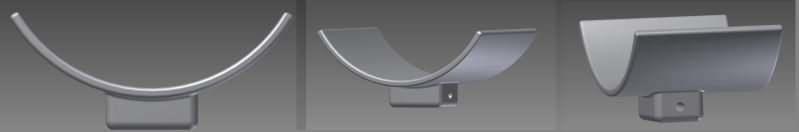

No, that's actually my plan too. The hole in the bottom of the mount is for the roller shaft. You probably can't tell, but the whole thing is offset an inch back so that the cradle will tilt backward when the boat isn't on. This makes sliding the boat onto the cradles easier because they should already be oriented correctly.

Another idea that I had was to put a spring on the roller shaft on each side of the cradle to allow it to move slightly to side to side but keep it in the same general location. But now that I've heard from the people that posted earlier, I'm afraid that allowing the cradle to slide side to side may put unneeded pressure on the hull sides.

--

-Zach

-- -

- Rank: Mate

- Registered: Aug 13, 2010

- Last visit: Mar 10, 2014

- Posts: 294

Actually.. I think that a bit of side to side is good.. No pressure on the hull walls but all on the bottom where it is designed to be. These hulls were designed to take pressure and wear on the keel. My H17 has cracks in the side of the hull from too much pressure from the tie-downs.. let the hulls find their own good spot during loading. Aft.. tilt downward to assist in getting the boat moving forward on the trailer.. Make the fore cradles less tippy but still have a bit of side to side to line up !! Let the tie down hold the boat. Not too unlike what the rollers have done for years.. The center of the hulls often times did not sit in the exact center of the rollers. With the new style boats,(a bit wimpy) support the keel, unlike the old time undestructable hobies which were so solid. Will post my design soon.. Hal

--

Hal Liske

Livermore CA

H 16 (6+ 1.. Friends) H 3.2 N 5.2 (2) H 17 (2) H-18

Nacra 5.8 (son's) H 20 (Friends)

It's a Sickness

I Need a A Cat Please

-- -

- Rank: Lubber

- Registered: Jul 04, 2004

- Last visit: Sep 29, 2020

- Posts: 26

The best trailer mod I have made so far is a 26 gallon fresh water wash down tank with about 30 foot of water hose, and a pump. I'll get a picture ASAP. The new trailer I have in my head is awesome.

Ernie

--

Ernie Kamp

http://www.youtube.com/user/TopSpin80#g/u

Richmond / Livingston / Galveston / Kemah / Texas City, Texas

Supercat 19 and Blade F16 "Nauti Habit", 2 Sunfish

-- -

- Rank: Mate

- Registered: Apr 24, 2011

- Last visit: Mar 20, 2018

- Posts: 177

D

Cool idea. I'd like to see it. I assume this is to rinse uour boat after each sail. Do you get enough flow to really rinse it?

--

-Zach

-- -

- Rank: Chief

- Registered: Apr 19, 2011

- Last visit: Dec 10, 2024

- Posts: 1461

This is a great idea! Locally we have a problem with the Invasive Quagga Mussels and are required to wash the hulls inside and out after sailing in a lake with known infestations. Have to use a vinegar solution. Looking forward to seeing your mod and what kind of pump you are using.

208 pounds of water... Did you balance this tank over the axle, or add it to the tongue weight?

--

Sheet In!

Bob

_/)_____/)_/)____/)____/)_____/)/)__________/)__

Prindle 18-2 #244 "Wakizashi"

Prindle 16 #3690 "Pegasus" Sold (sigh)

AZ Multihull Fleet 42 member

(Way) Past Commodore of Prindle Fleet 14

Arizona, USA

-- -

- Rank: Mate

- Registered: Jul 06, 2008

- Last visit: Jul 19, 2018

- Posts: 986

We are required to have a decontamination done by someone at the ramp with VERY hot water in the lakes that are known to be infested. All others have to fill out a form or take on online course to get an annual pass that says that you have completely dried out all parts of your boat and other stuff for a sufficient period to desiccate any possible travelers. The length depends on the time of years.

None of the lakes I go to so far are known to be infested but there are 3 in the state. i just take the online course every year and get the annual pass. I usually have more than enough time for everything to dry out good if I am diligent about getting the water out of the hulls.

--

Dustin Finlinson • Magna, UT

Member: Utah Sailing Association

1982 Prindle 18

1986 Hobie 17

1982 Prindle 16

1980 Prindle 16(mostly)

1976 Prindle 16(mostly)

Check out "Prindle Sailors" on Facebook.

-- -

- Rank: Mate

- Registered: Apr 24, 2011

- Last visit: Mar 20, 2018

- Posts: 177

Just a suggestion for others, I just bought a spare hub for emergencies. My hub only costs $30 at harbor freight and is pretty easy to change on the side of the road if the hub fails. I figure if/when a hub fails, I will be 100 miles or more from a place to buy a new hub.

I have brand new hubs on there now but for $30, its good insurance.

I'm an Eagle Scout so I want to be 100% prepared for my 1000+ mile trip to Florida next month.

--

-Zach

-- -

- Rank: Mate

- Registered: Aug 22, 2011

- Last visit: Oct 10, 2018

- Posts: 187

Zach,

Is this you????

http://tippecanoe.craigsl….org/boa/2959058939.html

BTW GO Boilermakers! I'm a former Indiana boy, living a little further north now, gotta lot of friends that went to school down there. I ended up at ball state, finishing up my engineering degree at Grand Valley State now, even though I've been a project engineer for almost 7 years, haha.

--

Cesar (Cez) S.

Hobie 16 (had a few)

Nacra 5.2 "Hull Yeah"

Vectorworks XJ - A class (not named yet)

West Michigan (Grand Rapids/Holland Area)

-- -

- Rank: Mate

- Registered: Apr 24, 2011

- Last visit: Mar 20, 2018

- Posts: 177

That'd be me. I've had good luck finding boats and parts from that ad. Yes, Boiler Up! I'm about to finish my Junior year in electrical engineering.

Edited by PurdueZach on Apr 21, 2012 - 09:37 AM.

--

-Zach

-- -

- Rank: Mate

- Registered: Jan 24, 2012

- Last visit: Feb 26, 2016

- Posts: 173

I redid a trailer over the winter too; it is lots of work. The box came from the donated trailer but needed work. The tube came with the boat (Nacra) trailer and needs work (someone painted it, Really?). The spin pole is nestled in the middle. The mast cradle is far enough forward to allow the spinaker pole to stay on while on the trailer. I 'dry sail' the boat so all I have to do is remove the bag and kite and leave the pole on the trailer.

Anyhow, I had the trailer sand blasted (it needed it bad), painted (roller) with primer and then paint (roller again), built the deck, reinstalled cradles, added new wiring/lights, a tongue wheel (used) and it is good to go. I find having a tube and box is really nice. The box holds all the stuff, dagger boards rudder etc and the tube protects the sails so no chafing.

My 18 trailer which I built in the early 90s is very similar but is a stacker (duh you can see the pic). It also has an older car topper on the front for jackets, harness, cooler etc. The thing I like is going to the lake with food and beer and all the sailing stuff is already there, makes it impossible to forget stuff (almost) I am fortunate to be able to stack the boats for the winter in a barn. The below pic is just after coming out of the barn and getting ready to put the nacra on the redone trailer.

If I were to do it again, I would never ever do a painted trailer again. The one I built is Hot dipped Galvanized and looks just as good today as it did when I built it. The redone trailer is the same age and was it terrible shape. Sorry if I am hijacking the topic.

--

Lake Perry KS

H-18

N-5.5 UNI +spin

-- -

- Rank: Mate

- Registered: Jul 06, 2008

- Last visit: Jul 19, 2018

- Posts: 986

I'd love to some up close pics of how your double stack is setup. I really need that on mine soon.

--

Dustin Finlinson • Magna, UT

Member: Utah Sailing Association

1982 Prindle 18

1986 Hobie 17

1982 Prindle 16

1980 Prindle 16(mostly)

1976 Prindle 16(mostly)

Check out "Prindle Sailors" on Facebook.

-- -

- Rank: Mate

- Registered: Apr 24, 2011

- Last visit: Mar 20, 2018

- Posts: 177

You're not threadjacking at all. I meant for this to be more of a show and tell rather than for me to show what I have done. I'm looking for ideas to make mine better all the time. I'm leaving for Florida in exactly 3 weeks and I'm oddly excited for the 1100 mile journey with the trailer. Now the only problem is that I have 2 free boats in the works (to be picked up next week) that I need to find a way to break them down and bring with me. If nothing else, I'll keep the good parts and give away anything that friends in Florida may need.

Word

--

-Zach

-- -

- Rank: Mate

- Registered: Jan 24, 2012

- Last visit: Feb 26, 2016

- Posts: 173

The Y frame of the trailer is not bent it is side welded to the long frame on each side. This leaves the ends open and allow the racks to slide in. There are holes in the racks and on the trailer for 1/2 inch hitch pins or bolts. The rack sits on the bottom of the tubing and bolts hold them, I never snug them to avoid crushing the tube, I use nylocs and they do the job. I can get pix of the racks in the am, if you click on the pic above it gets bigger and you can see the idea. What you can not see is the mast cradle has two mast racks. The Hobie 18 and trailer are already at the dry sail area so I will not get pix of that for a couple of weeks.

The down side is the trailer is heavier as all the tubing is thicker and stronger and I had to upgrade the axle and tires. All this is fine when you start from scratch but not so good when starting with a thin wall trailer with a light duty axle and light duty tires. I am running Trailer wheels and multi ply trailer tires in 13 inch. The tongue is longer, the cradles and rollers are further apart to accomodate the racks. The whole thing was built twice (more like 3 times), more holes drilled for light wiring, the axle is on a movable frame so I can get the tongue weight right, the main tongue is removeable so if it gets bent it can un bolt, the list of custom stuff goes on and on. I would not modify the new trailer to be a stack it is just not strong enough to start with. It was enough work that I did two and decided not to do any more than that. Even doing two I spent a grand on parts before galvanizing and that was in the late 80s (crap I am old) HTH, Ricardo.

--

Lake Perry KS

H-18

N-5.5 UNI +spin

--