Here are a couple of things I have done to reduce the rudder down line jam problem. Based on Nick Drapes suggestion I tied my bowline at "just the right" point on the down line so that the knot engages the strap/shackle just as the rudder reaches the full up position.

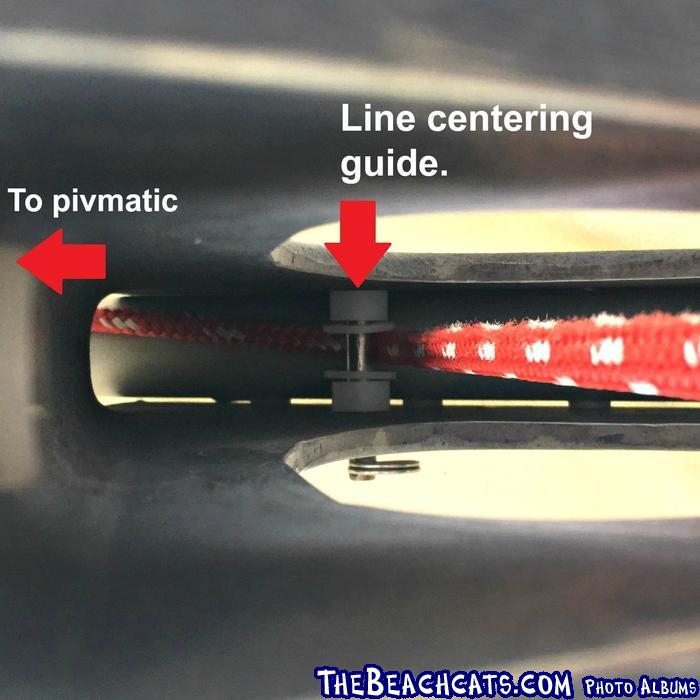

Second, I installed spacers and washers that act as a centering guide on the clevis pin turning point. This will help keep the line from wondering to the side.

My next step will be to take P.M.'s suggestion on line as the the New England Sta-Set indeed does stretch a lot and is not the greatest choice for this application.

--

Hobie 16 (3 formerly)

MacGregor 25 (formerly)

Chrysler Dagger 14 (formerly)

NACRA 5.0 (currently)

High Point, NC

--